Is Kaizen used in Lean or Six Sigma

Kaizen in relation to Lean Six Sigma

Kaizen goes even further in regards to the awareness of the management and the employees. Lean Six Sigma, on the other hand, is more focused on the financial results of the organization. Kaizen works best if the entire organization works together.

Is Kaizen a Lean

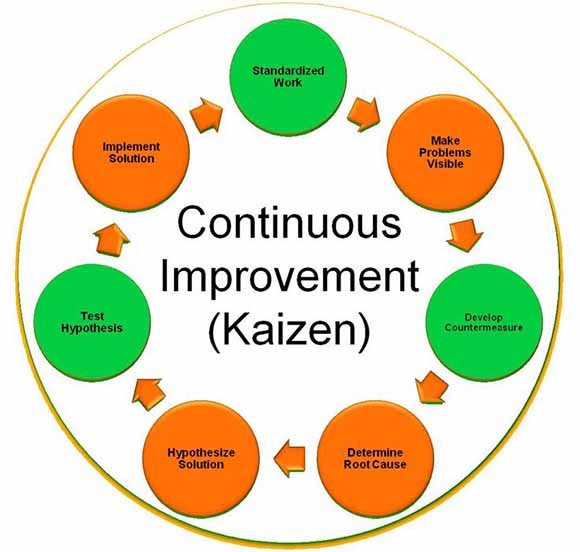

Kaizen, or rapid improvement processes, often is considered to be the "building block" of all lean production methods. Kaizen focuses on eliminating waste, improving productivity, and achieving sustained continual improvement in targeted activities and processes of an organization.

What is the difference between Kaizen and Lean and Six Sigma

While Kaizen and Lean both look at resources and ways to optimize a process, the core goal of Six Sigma is achieving consistent and reliable results. It is primarily focused on improving the quality of the result or outcome of the process.

Is Kaizen better than Six Sigma

If the goal is to achieve near-perfect levels of quality, Six Sigma may be the best approach. However, if the goal is to create a culture of continuous improvement with a focus on efficiency and waste reduction, then Kaizen may be a better fit.

Is 5S Lean or Six Sigma

The 5S system is a key component of Lean Six Sigma. Developed at Toyota, the 5S approach creates safer, more efficient workstations that allow employees to improve and sustain higher productivity. The term 5S refers to the five steps of the system.

Is Kaizen part of 5S

5S is derived from the philosophy of "kaizen", which simply means "continuous improvement". Japanese automotive manufacturer, Toyota, states that the philosophy of "kaizen" is one of its core values. This philosophy is supported by three key principles, one of which is 5S.

Is Kaizen and 5S same

5S is derived from the philosophy of "kaizen", which simply means "continuous improvement". Japanese automotive manufacturer, Toyota, states that the philosophy of "kaizen" is one of its core values. This philosophy is supported by three key principles, one of which is 5S.

Is Kaizen part of TQM

The Total Quality Management (TQM) practices has developed a strong bearing on growth and competitiveness in market. Therefore, a proper continuous improvement (Kaizen) practice is needed to eliminate waste and value added in production to remain competitiveness and retained the potential customer.

What is 5S vs Kaizen vs Six Sigma

With Kaizen's focus on culture, 5S's on environment, Lean on waste and Six Sigma on defects and quality, we have a powerful combination of tools poised to transform organizations. What if Kaizen, Lean, 5S and Six Sigma are applied from time of booking a surgical case to hospital discharge and/or rehab

Is Kaizen similar to TQM

True (Total quality management, moderate)

Kaizen is similar to TQM in that both are focused on continuous improvement.

Is 5S lean or Six Sigma

The 5S system is a key component of Lean Six Sigma. Developed at Toyota, the 5S approach creates safer, more efficient workstations that allow employees to improve and sustain higher productivity. The term 5S refers to the five steps of the system.

Is TQM a Six Sigma

TQM defines quality as the process meeting the standards established by the organization. But, Six Sigma defines it as the process with minimum amounts of defects. This is why TQM delivers superior quality manufactured goods, while Six Sigma delivers better results and customer satisfaction.

Is 5 sigma better than 6 Sigma

The higher the sigma level the better the quality of the product or service and the fewer the defects. Organizations with a Six Sigma quality have an advantage over others who perform at three, four or even five sigma levels.

Is Kaizen a TQM

TQM means organized Kaizen activities involving everyone in a company, managers and workers in a totally universal and integrated effort toward improving performance at every level.

Is TQM part of Lean

In this context, TQM can be tools and techniques of Lean considering that TQM comprises hard aspects including the different tools and techniques is designed to implement Lean principles.

Is 5S part of Lean or Six Sigma

The 5S system is a key component of Lean Six Sigma. Developed at Toyota, the 5S approach creates safer, more efficient workstations that allow employees to improve and sustain higher productivity. The term 5S refers to the five steps of the system.

Why Six Sigma is not 5 sigma

The more number of standard deviations between process average and acceptable process limits fits, the less likely that the process performs beyond the acceptable process limits, and it causes a defect. This is the reason why a 6σ (Six Sigma) process performs better than 1σ, 2σ, 3σ, 4σ, 5σ processes.

Is 6 sigma a TQM

Six-Sigma is a relatively newer concept than Total Quality Management but not exactly its replacement. The basic difference between Total Quality Management and Six Sigma is that TQM delivers superior quality manufactured goods whereas six sigma on the other hand results in better results.

Why is Six Sigma different from Kaizen

Six Sigma aims for perfection, or zero defects, as often as possible, while Kaizen aims to continuously improve the overall work environment, the systems in place and the strategies used without focusing on percentile success rates.

Is Kanban a Six Sigma

The main difference is that Kanban uses visualization as the main tool for spotting and eliminating problems, while Lean Six Sigma relies on statistical data and analysis. Additionally, Kanban focuses on the (working) team and is process-oriented. And Lean Six Sigma is customer-focused and process-oriented.

Is DMAIC the same as Kaizen

Kaizen™ and DMAIC are both business approaches with Kaizen™ being similar to Lean methodology and DMAIC similar to Six Sigma.

Are Kaizen and Kanban the same

Both were derived from the lean manufacturing methodology of the Toyota Production System. While Kanban is a tool for visualizing a process and identifying bottlenecks, the Kaizen approach is a continuous improvement process.

Is Kanban Lean or Agile

Scrum is a set of practices and tools to implement the ideas of Agile. Kanban is a set of practices and tools to implement the ideas of Lean.

Is Kanban Lean or Six Sigma

Kanban is a visual Lean Tool and is often applied in combination with JIT (Just-In-Time). Components are only produced when they are needed. Kanban comes from the Japanese words 'kan', which means 'visual' and 'ban', which means 'card' or 'board'.

Is Kanban part of Lean Six Sigma

Lean project management is the foundation for Kanban and Lean Six Sigma. So it's no surprise they share a common goal – improving efficiency through smarter use of resources and eliminating bottlenecks (waste).