What are the 10 rules of lean production

Principles of lean production include: eliminating waste; minimizing inventory; maximizing flow; pulling production from customer demand; meeting customer requirements; doing it right first time; empowering workers; designing for rapid changeover; partnering with suppliers; creating a culture of continuous improvement …

What are the main components of lean production

Lean production is an approach to management that focuses on cutting out waste, whilst ensuring quality. This approach can be applied to all aspects of a business – from design, through production to distribution. Lean production aims to cut costs by making the business more efficient and responsive to market needs.

What are 9 Lean manufacturing principles

The 9 principles discussed are: Continuous Flow, Lean Machines/Simplicity, Workplace Organization, Parts Presentation, Reconfigurability, Product Quality, Maintainability, Ease of Access, and Ergonomics. The preferred shape of the lean workcell is U-shaped. Each subprocess is connected to the next in order of process.

What are the 5 primary elements of Lean

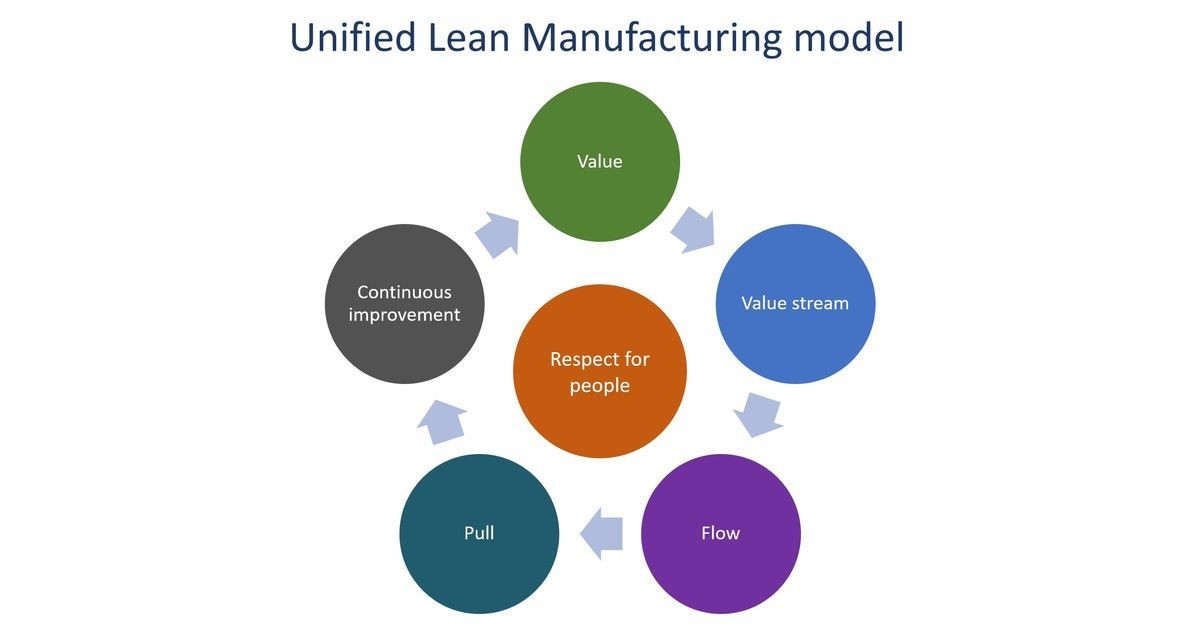

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

What are the 7 areas of lean

The Lean theory describes 7 major areas where you can identify Muda activities, more popular as the seven wastes of Lean.Transportation. This type of waste is when you move resources (materials), and the movement doesn't add value to the product.Inventory.Motion.Waiting.Overproduction.Over-processing.Defects.

What are the 5 Ms of lean manufacturing

Lean is an all-encompassing philosophy that takes the 5 M's (Man, Material, Machines, Methods, and Money) and harmonizes or helps orchestrate them together for the best possible outcome in your manufacturing operations. If you do not know the 5 M's, here's a brief overview of how the 5 M's relate to lean automation.

What are the 4 elements of lean management system

To me, it's easier to think of the definition in four elements.Element 1: To Serve and Develop People.Element 2: Through Human Interactions and Relationships.Element 3: Toward the Achievement of Goals that Support Purpose.Element 4: Creating More Value for All Stakeholders.

What are the 8 Lean principles

To help focus efforts in this area, Lean practitioners developed a list of eight wastes which establish the most likely areas where waste will occur: defects, overproduction, transportation, non-value adding processing, motion, waiting, unused talent and inventory.

What are the 7 steps lean manufacturing

What is lean manufacturing The top 7 principles for manufacturers to improve processes1) Elimination of waste.2) Valuing the human element.3) Seeking perfection.4) Mapping the value stream.5) Reducing and preventing mistakes.6) Identifying loss of value.7) Automatically finding defects.

What are the 11 characteristics of a lean system

The 11 characteristics are as follows: Waste reduction— Continuous improvement— Use of teams— Work cells— Visual controls— High quality— Minimal inventory— Output tied to demand— Quick. There are 11 characteristics of a lean system.

What are the 5 dimensions of lean

Lean implementation is comprised of five main dimensions, which are transactional, organizational, spatial, time, and resources. Collectively, these dimensions help companies function more effectively and efficiently throughout the production process.

What is Lean 7 principles

Lean software development is a concept that helps build the right product in the right way. It is based on seven key principles: eliminating waste, amplifying learning, deciding late, delivering fast, empowering the team, building quality in, and optimizing the whole.

What are the 7 ways in Lean

The Lean theory describes 7 major areas where you can identify Muda activities, more popular as the seven wastes of Lean.Transportation. This type of waste is when you move resources (materials), and the movement doesn't add value to the product.Inventory.Motion.Waiting.Overproduction.Over-processing.Defects.

What is lean 7 principles

Lean software development is a concept that helps build the right product in the right way. It is based on seven key principles: eliminating waste, amplifying learning, deciding late, delivering fast, empowering the team, building quality in, and optimizing the whole.

What are the ten characteristics of a lean enterprise

Every Lean organization is unique, but there are some core qualities that they tend to have in common.Focused. Lean organizations are obsessed with customer value.Aligned.Humble.Collaborative.Tenacious.Engaged.Methodological.Proactive.

What are the 5 dimensions of Lean

Lean implementation is comprised of five main dimensions, which are transactional, organizational, spatial, time, and resources. Collectively, these dimensions help companies function more effectively and efficiently throughout the production process.

What are the 7S in Lean Six Sigma

The Lean 7S is the latest methodology which comprises of the seven phases namely Sort, set in order, Shine, Standardize, Sustain or Self Discipline, Safety and Spirit (team Spirit).

What are the 7 core competencies of the lean enterprise

The seven core competencies of lean enterprise are agile frameworks, efficient processes, customer focus, organizational ability, continuous learning, product and technology development, and business acumen.

What is the 7S model summary

The McKinsey 7S Model refers to a tool that analyzes a company's “organizational design.” The goal of the model is to depict how effectiveness can be achieved in an organization through the interactions of seven key elements – Structure, Strategy, Skill, System, Shared Values, Style, and Staff.

What is the 7S model explanation

The McKinsey 7-S Model is a change framework based on a company's organizational design. It aims to depict how change leaders can effectively manage organizational change by strategizing around the interactions of seven key elements: structure, strategy, system, shared values, skill, style, and staff.

What are the 6 common core competencies

The six competencies (Leadership, Communications, Readiness, Training Management, Operations, and Program Management) taught in NCO Professional Military Education (PME) are common to all Noncommissioned Officers regardless of Military Occupational Specialty (MOS), rank, or position.

What are the 6 key competencies

THE SIX COMPETENCIES: CREATIVITY, COMMUNICATION, CRITICAL THINKING, COLLABORATION, CITIZENSHIP AND CONNECTIVITY FOR THE FUTURE EDUCATION.

What are the 7S principles of management

What are the 7S Factors The seven factors are: strategy; structure; systems; shared values; skills; style; and staff.

What are the 7 steps of McKinsey

The seven elements- Structure, Strategy, Shared Values, Skill, System, Shared Values, Style, and Staff are highly interconnected. If change leaders fail to create a well-rounded action plan to restore the balance, a company can substantially lose out on business.

What is 7S in quality management

The Lean 7S is the latest methodology which comprises of the seven phases namely Sort, set in order, Shine, Standardize, Sustain or Self Discipline, Safety and Spirit (team Spirit).