What are the 3 types of Lean

The labels muda, mura and muri are also used in lean development, an Agile software methodology inspired by the Toyota Way.

What are 3 examples of lean manufacturing

Here are a few examples:Truck Manufacturing: Improving production levels and efficiency.Customer Service: Streamlining the work process by mapping the value stream.Process Automation: Improving transparency and flow tracking.Innovation culture: Improving learning and knowledge sharing.

What are the 3 main Lean ideas

Lean Basics

The Lean approach to business processes, originally derived from the enormously influential Toyota production system (TPS) , is based on three fundamental principles: delivering value as defined by the customer, eliminating waste, and continuous improvement.

What are the main methods of lean production

These are:The key aspects of lean production that you should be aware of are:Time based management.Simultaneous engineering.Just in time production (JIT)Cell production.Kaizen (Continuous improvement)Quality improvement and management.

What is Stage 3 of a Lean process

How do you get to the root of the problem How do you determine the true source of the issue so you can solve the problem for good That is the crux of an improvement effort and the key focus of the Analyze Phase.

What are the 3ms of lean manufacturing

Muda, Mura, and Muri are terms often used together in the Toyota Production System (and called the Three Ms) that collectively describe wasteful practices to be eliminated.

What are 3 benefits of lean production

Lean manufacturing improves efficiency, reduces waste, and increases productivity.

What are the 5 lean manufacturing tools

The goal of lean manufacturing is to find better ways to do things: requiring less effort, less time, and fewer resources. Some lean tools may be more appropriate for one business than another. However, Kaizen, 5S, Kanban, Value Stream Mapping, and Focus PDCA are among the most useful lean tools.

What are the 3 key stages of the 3S improvement cycle

At a high-level, the 3S Process consists of three stages (Story, Strategy, and Solution), which are described in detail in the article. Stage 1: Story in the process is inspired by the Harvard Case Method to provide context for a problem.

What are the 4 rules of lean

Kent Bowen boiled down the essence of all lean systems to these Lean 4 Rules In Use:Rule 1) Clearly specify all Activities.Rule 2) Clearly define all Connections. to every customer and supplier.Rule 3) Clearly define all Pathways.Rule 4) Continuously Improve.

What are the 5 elements of lean production

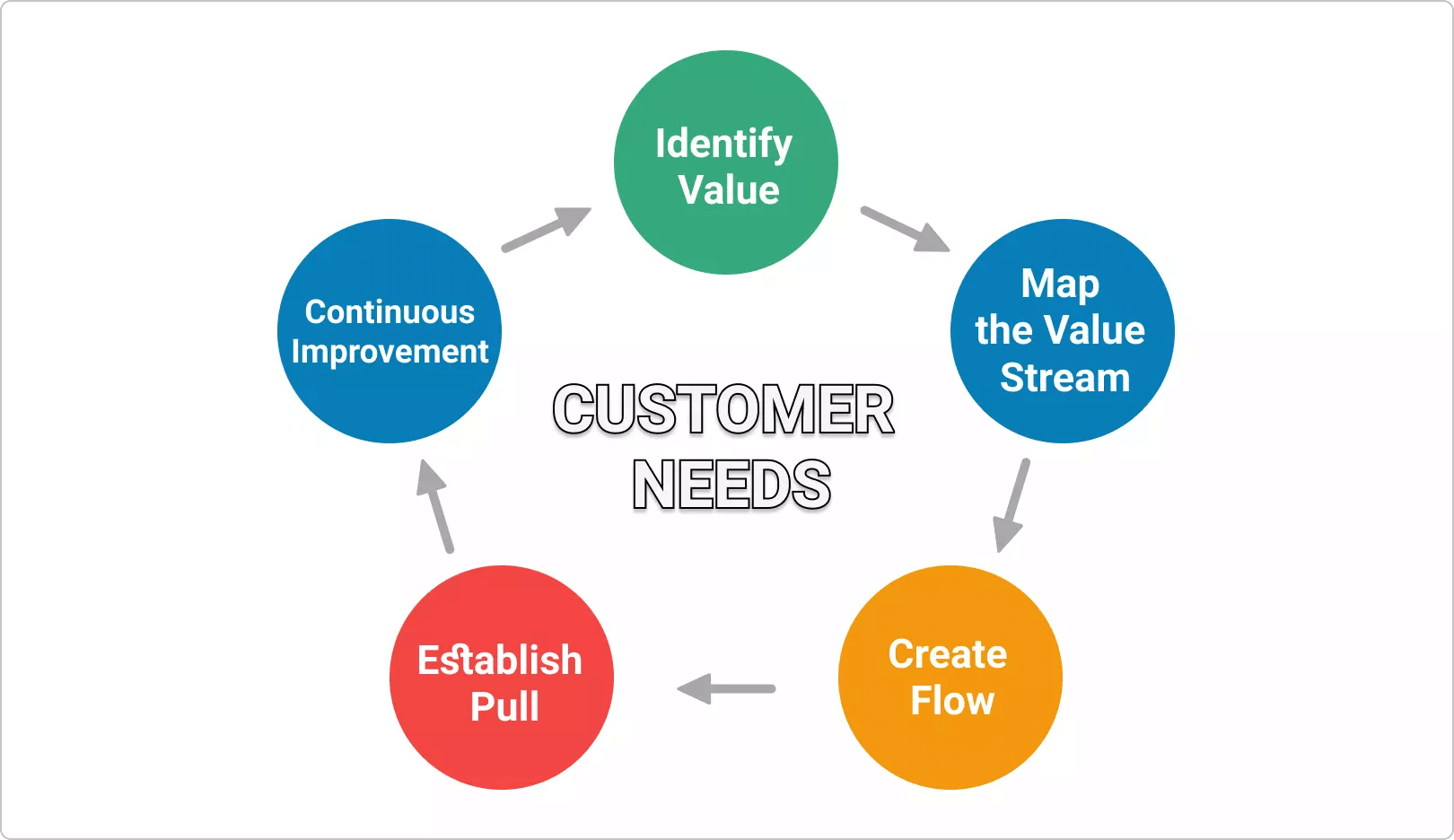

According to Womack and Jones, there are five key lean principles: value, value stream, flow, pull, and perfection.

What are the 5 principles of lean production

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

What is 3R lean manufacturing

The 3R Initiative aims to promote the "3Rs" (reduce, reuse and recycle) globally so as to build a sound-material-cycle society through the effective use of resources and materials.

What are the 4 stages of Lean methodology

The 4 Steps of the Lean Startup CycleStep #1 – Business Model Canvas.Step #2 – Formulating a Hypothesis.Step #3 – Minimum Viable Product (MVP)Step #4 Learning.

What are the 4M in Lean

4M (Man, Machine, Material, Method):

Common structure for potential causes for Problem Solving methods, for example as the bones of the fish-bone diagram (see Ishikawa Diagram). This is often expanded into 8M, including additionally management, milieu, measurement, and money.

What is 3M Lean Six Sigma

Lean Six Sigma at 3M

3M has also been a pioneer in the use of Lean Six Sigma methods and tools to improve operations and quality. (Lean Six Sigma is a process-improvement methodology and a collection of statistical tools designed to reduce process variation and improve product quality.)

What are the 5 principles of lean

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

What is lean methodology used for

What methodology is lean Lean is a continuous improvement methodology that originated in the manufacturing industry, specifically at Toyota Motor Corporation in Japan. It is a systematic approach to identifying and eliminating waste in processes to deliver more value to customers with fewer resources.

What are the 7 ways in lean

The Lean theory describes 7 major areas where you can identify Muda activities, more popular as the seven wastes of Lean.Transportation. This type of waste is when you move resources (materials), and the movement doesn't add value to the product.Inventory.Motion.Waiting.Overproduction.Over-processing.Defects.

What are the 7 steps lean manufacturing

What is lean manufacturing The top 7 principles for manufacturers to improve processes1) Elimination of waste.2) Valuing the human element.3) Seeking perfection.4) Mapping the value stream.5) Reducing and preventing mistakes.6) Identifying loss of value.7) Automatically finding defects.

What is the 3S methodology

3S Understanding is a curriculum structure that was created by James G. Henderson. 3S Understanding is a mixture of three components that can be diagrammed as a triangle. The three Ss are Subject Matter, Self-learning, and Social Learning.

What is 3S in production management

The 3S audit process consists of 3 steps: Sort, Set in Order, and Shine. With these three steps, manufacturers can ensure their facility complies with safety and quality standards.

What are the 5 stages of lean

What Are the 5 Lean Management PrinciplesIdentifying Value. To lay the foundations of a Lean process, you need first to identify the team's work value.Mapping the Value Stream. The second of the 5 principles of Lean is all about the stream of value.Creating a Flow.Establishing Pull.Seeking Constant Improvement.

What are the 7 ways in Lean

The Lean theory describes 7 major areas where you can identify Muda activities, more popular as the seven wastes of Lean.Transportation. This type of waste is when you move resources (materials), and the movement doesn't add value to the product.Inventory.Motion.Waiting.Overproduction.Over-processing.Defects.

What are the 4 rules of Lean

Kent Bowen boiled down the essence of all lean systems to these Lean 4 Rules In Use:Rule 1) Clearly specify all Activities.Rule 2) Clearly define all Connections. to every customer and supplier.Rule 3) Clearly define all Pathways.Rule 4) Continuously Improve.