What are the three types of lean production

The Toyota Production System, and later on the concept of Lean, was developed around eliminating the three types of deviations that shows inefficient allocation of resources. The three types are Muda (無駄, waste), Mura (斑, unevenness), and Muri (無理, overburden).

What are the 3 components of lean manufacturing

The Lean approach to business processes, originally derived from the enormously influential Toyota production system (TPS) , is based on three fundamental principles: delivering value as defined by the customer, eliminating waste, and continuous improvement.

Which are the 3 main tools in lean management

What Are Lean Tools

| Lean Tools | Summary |

|---|---|

| Just-in-Time (JIT) | On-demand system of production |

| Value Stream Mapping | Analyzing and optimizing a process |

| Overall Equipment Effectiveness (OEE) | Measure of productive time |

| Plan-Do-Check-Act (PDCA) | Method to manage change |

What are the 4 methods of lean production

These are:The key aspects of lean production that you should be aware of are:Time based management.Simultaneous engineering.Just in time production (JIT)Cell production.Kaizen (Continuous improvement)Quality improvement and management.

What are 3 benefits of lean production

Lean manufacturing improves efficiency, reduces waste, and increases productivity.

Which are the type of Lean

The 8 Essential LEAN Techniques You Need to KnowLean Techniques #1 Kaizen.Lean Techniques #2 Poka-Yoke.Lean Techniques #3 5S.Lean Technique #4 KANBAN.Lean Techniques #5: Just In Time.Lean Technique #6 Jidoka.Lean Techniques #7 Takt time.Lean techniques #8 Heijunka.

What is the lean production method

Lean production is a production methodology focused on eliminating waste, where waste is defined as anything that does not add value for the customer. Although Lean's heritage is manufacturing, it is applicable to all types of organisation and all an organisation's processes.

What is the lean production model

The lean production model examines production with the goal of increasing company profit by focusing on cost reduction and waste elimination in the organization. Any process that doesn't add value to the customer is considered waste that could be eliminated to save money.

What are the 5 core tools Lean

What are the 5 Core Quality ToolsAPQP (Advanced Product Quality Planning)PPAP (Production Part Approval Process)FMEA (Failure Mode and Effects Analysis)MSA (Measurement Systems Analysis)SPC (Statistical Process Control)

What are the 5 primary elements of Lean

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

What are the 5 elements of lean production

According to Womack and Jones, there are five key lean principles: value, value stream, flow, pull, and perfection.

What are the 5 Lean principles

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

What are the 5 principles of lean

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

What is Kaizen lean production

Kaizen focuses on eliminating waste, improving productivity, and achieving sustained continual improvement in targeted activities and processes of an organization. Lean production is founded on the idea of kaizen – or continual improvement.

What is lean type of production system

What is it Lean production is a production methodology focused on eliminating waste, where waste is defined as anything that does not add value for the customer. Although Lean's heritage is manufacturing, it is applicable to all types of organisation and all an organisation's processes.

What are the 5 elements of lean

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. The next sections provides a detailed overview of each principle.

What are the 5 principles of lean production

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

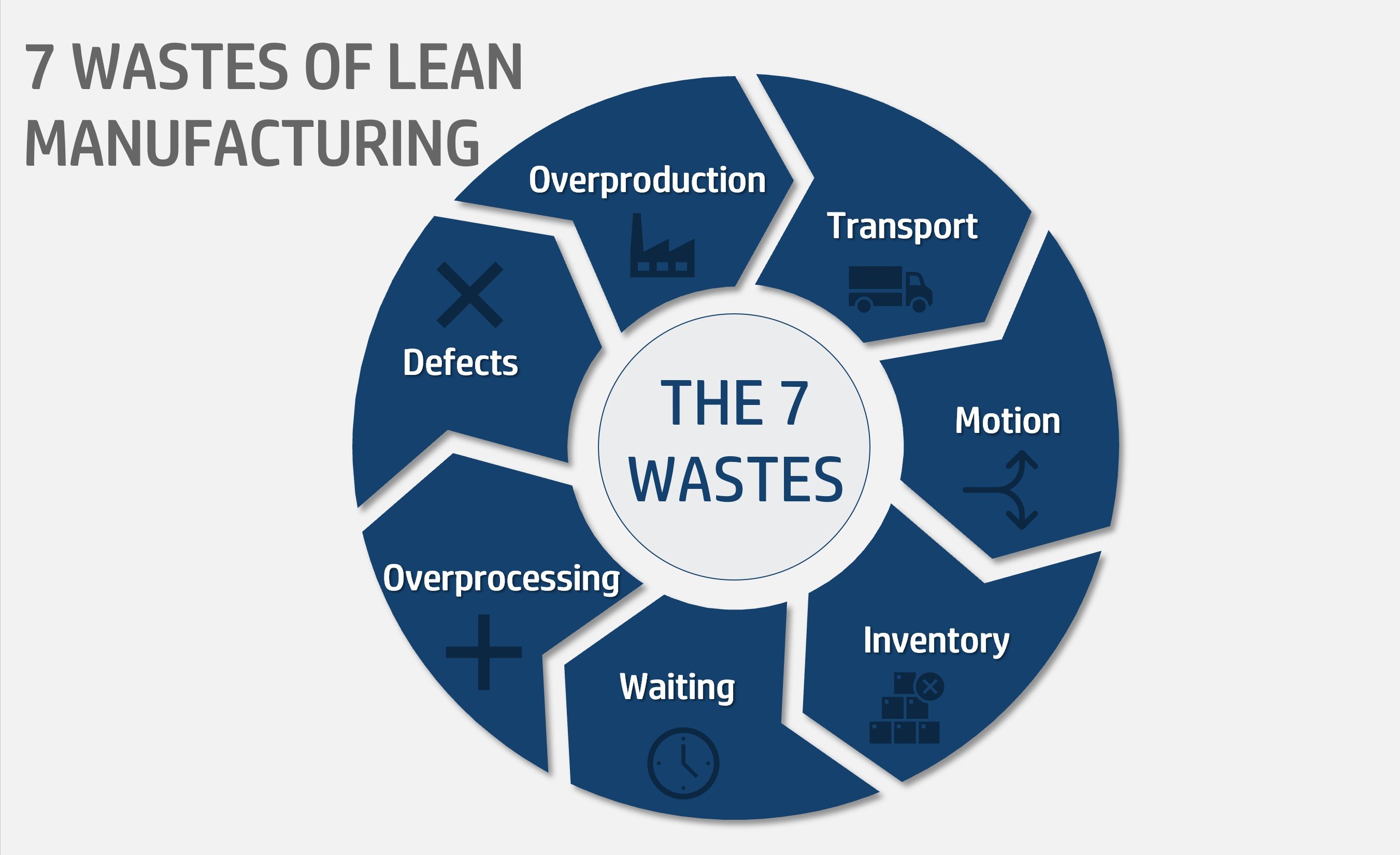

What are the 7 ways in lean

The Lean theory describes 7 major areas where you can identify Muda activities, more popular as the seven wastes of Lean.Transportation. This type of waste is when you move resources (materials), and the movement doesn't add value to the product.Inventory.Motion.Waiting.Overproduction.Over-processing.Defects.

What are the 5 dimensions of lean

Lean implementation is comprised of five main dimensions, which are transactional, organizational, spatial, time, and resources. Collectively, these dimensions help companies function more effectively and efficiently throughout the production process.

What are the 10 basic elements of lean production

To help you gain a comprehensive understanding of lean manufacturing, here are 10 things you should know:Leveled Production.Continuous Improvement.Efficiency Through a Customer-First Approach.Total Productive Maintenance (TPM)Streamlining Processes.Develop Error-Proof Processes.Focus on Quality.One-Piece Flow.

What are the 7 steps lean manufacturing

What is lean manufacturing The top 7 principles for manufacturers to improve processes1) Elimination of waste.2) Valuing the human element.3) Seeking perfection.4) Mapping the value stream.5) Reducing and preventing mistakes.6) Identifying loss of value.7) Automatically finding defects.

What is 5S concept

5S is a five-step methodology for creating a more organized and productive workspace: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.

Is Kaizen Lean or Six Sigma

Kaizen in relation to Lean Six Sigma

Kaizen goes even further in regards to the awareness of the management and the employees. Lean Six Sigma, on the other hand, is more focused on the financial results of the organization. Kaizen works best if the entire organization works together.

Is Lean and Kaizen same

Lean is a methodology that eliminates waste and boosts efficiency. Kaizen means continuous improvement. This course merges both philosophies. Lean Kaizen helps you get rid of waste and continuously implement best practices.

What is the lean production process

Lean manufacturing is a production process based on an ideology of maximising productivity while simultaneously minimising waste within a manufacturing operation. The lean principle sees waste is anything that doesn't add value that the customers are willing to pay for.