What are the basic manufacturing processes

Bending, spinning, drawing, and stretching are a few important metal forming process in manufacturing. The metal press such as die and punching tools are implemented for this manufacturing process. Advantages: – Same equipment can be utilized for manufacturing various components by simply changing the dies.

What are the two basic manufacturing processes

Manufacturers typically carry out the manufacturing processes as a unit operation, which means it is a single step in a series of steps required to transform a starting material into a finished product. Processing operations and assembly operations are the two basic types of manufacturing operations.

What are the manufacturing processes of a machine

the "traditional" machining processes, such as turning, boring, drilling, milling, broaching, sawing,shaping, planing, reaming, and tapping, or sometimes to grinding.

What is manufacturing process in engineering

Manufacturing is defined as the conversion of raw materials into the finished goods on a large scale using man and machine whereas manufacturing processes are defined as the methods used for conversion of raw materials into finished products.

What are the 5 manufacturing process types

Five Types Of Manufacturing Processes:Repetitive Manufacturing. Basic manufacturing that creates the same product on an assembly line is engaged in the repetitive manufacturing process.Discrete Manufacturing.Job Shop Manufacturing.Continuous Process Manufacturing.Batch Process Manufacturing.

What are the 3 main production processes

Businesses providing goods can choose from three different types of production process. These are job production , batch production and flow production .

What are 5 steps of manufacturing process

Steps of the Manufacturing ProcessDevelop the Product Vision. The product vision is the seed the finished goods will grow from.Research the Vision.Design the Product.Finalize the Design.Test the Prototype.Manufacture the Product.Get Feedback and Do More Testing.Official Release.

What are the 7 steps of manufacturing

Steps of the Manufacturing ProcessDevelop the Product Vision. The product vision is the seed the finished goods will grow from.Research the Vision.Design the Product.Finalize the Design.Test the Prototype.Manufacture the Product.Get Feedback and Do More Testing.Official Release.

What are the 5 Ms of manufacturing

Lean is an all-encompassing philosophy that takes the 5 M's (Man, Material, Machines, Methods, and Money) and harmonizes or helps orchestrate them together for the best possible outcome in your manufacturing operations. If you do not know the 5 M's, here's a brief overview of how the 5 M's relate to lean automation.

What are the 5 activities of the production process

Five activities related to production are: Mobilisation of resources. Planning of production process. Actual production. The selection of a particular method of production and. Management of production process and monitoring are the five activities related with production .

Which of the 3 phases of production is the most important

Preproduction

Preproduction represents the planning process, which probably is the most significant stage of the production, as everything else depends on how carefully the stages of production are anticipated.

What are the 7 steps of production

Mastering the 7 Stages of Film ProductionDevelopment.Financing.Pre-production.Production.Post-production.Marketing.Distribution.

What are the 5 stages of manufacturing

Each stage has purpose and goals, and it is important that in each phase the goals are met before proceeding to the next. The 5 stages are development, pre-production, production, post-production, and distribution.

What are the 5 types of manufacturing

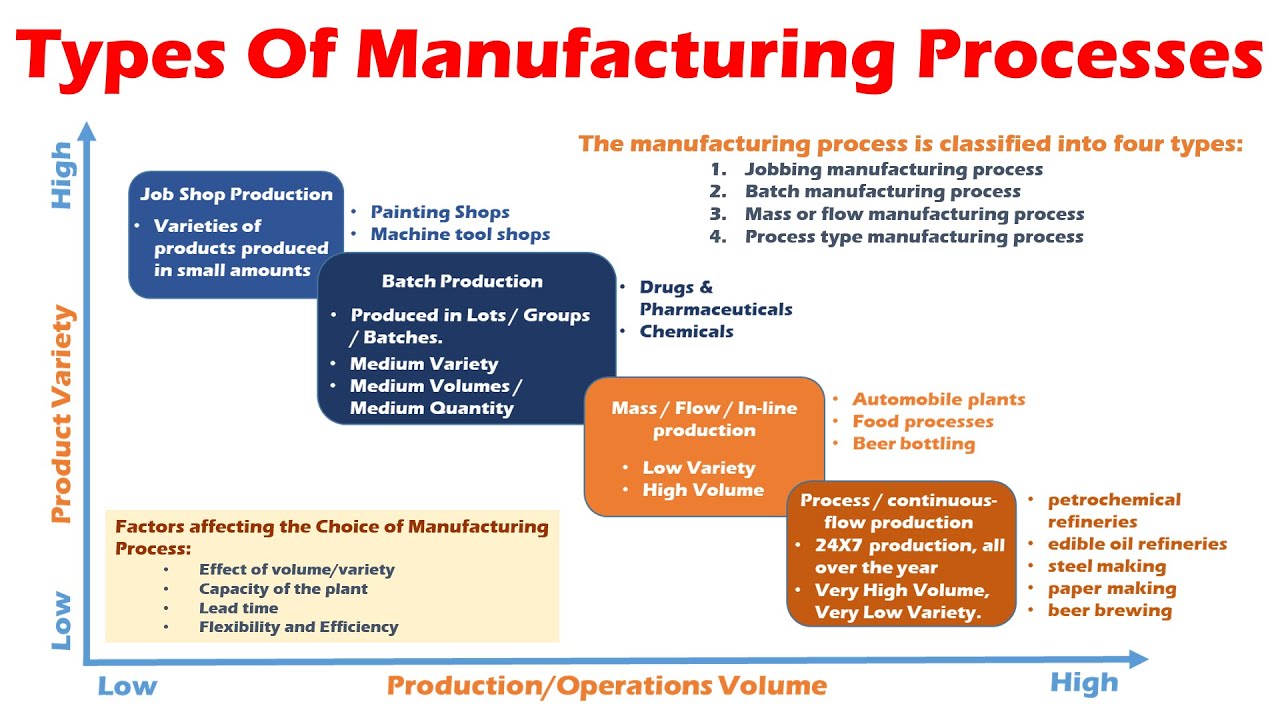

The five types of manufacturing processesRepetitive manufacturing.Discrete manufacturing.Job shop manufacturing.Process manufacturing (continuous)Process manufacturing (batch)

What are the 7 Ms of manufacturing

In this research systematic approach has been used for organization and production system inputs which named as 7Ms (Management, Manpower, Marketing, Method, Machine, Material, and Money).

What are the 6 Ms of manufacturing

2. What do the 6 Ms stand for Although the sequence may vary, the Ms stand for: Machinery, Materials, Methods, Measurement, Manpower, and Mother Nature.

What are the 5 types of production

The five main types of the production process are Mass production, Batch production, job production, Just-In-Time production, and flexible manufacturing system.

What are the 5 major stages of production planning and development process

This refining process—the product planning and development process—is divided into five major stages: idea stage, concept stage, product development stage, test marketing stage, and commercialization. These stages result in the start of the product life cycle (see Figure 4.1).

What are the three 3 types of production process

There are three common types of basic production systems: the batch system, the continuous system, and the project system. In the batch system, general-purpose equipment and methods are used to produce small quantities of output (goods or services) with specifications that vary greatly from one batch to the next.

What are the 3 stages of production

While we'll explore each more in-depth below, the three basic stages of the video production process are as follows:Pre-Production.Production.Post-Production.

What are the 5 stages of production

Each stage has purpose and goals, and it is important that in each phase the goals are met before proceeding to the next. The 5 stages are development, pre-production, production, post-production, and distribution.

What are the 8 stages in the new product development process

What are the 8 steps of successful new product developmentIdea generation.Idea screening.Concept development and testing.Marketing strategy development.Business analysis.Product development.Test marketing.Commercialisation.

What are the 4 Ms of manufacturing

By implementing best practices that address the 4Ms of Machines, Manpower, Methods, and Material.

What are the 8 M’s of manufacturing

EFFECTIVE FACTORS TO LEANNESS

The internal effective 8 Ms are: management, material, machine, manpower, method, money, measurement, minutes; the external 2 Ms are: market and ministry.

What are the 9 M’s of quality

The nine fundamental factors (9 M's), which are affecting the quality of products and services, are: markets, money, management, men, motivation, materials, machines and mechanization. Modern information methods and mounting product requirements.