What are types of manufacturing systems

TypesJob Shop Manufacturing: It produces a wide variety of products in small quantities.Batch Production: It produces small quantities of products.Flow Production: It produces large quantities of products.Lean Manufacturing: It minimizes waste, maximizes efficiency, and increases overall quality.

What are the basic manufacturing systems

All manufacturing falls under one of these five major manufacturing systems, running the gamut from bespoke products through mass manufacture to modern mass customization.Custom manufacturing system.Intermittent manufacturing system.Continuous manufacturing system.Flexible manufacturing system.Mass customization.

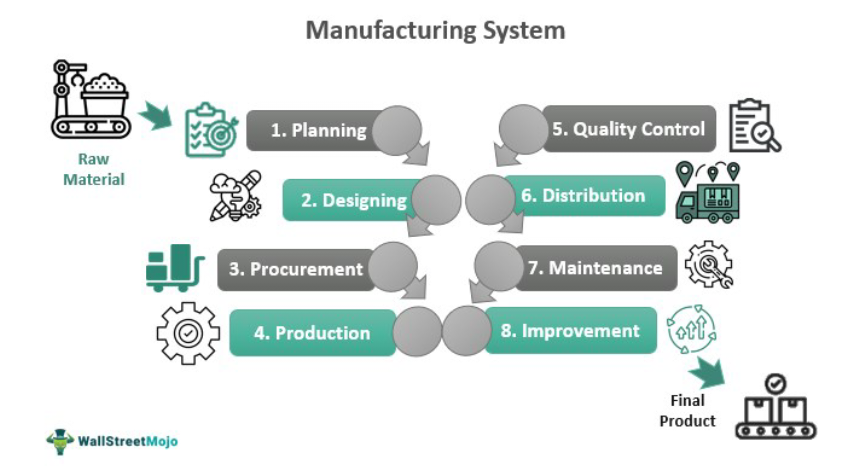

What is the manufacturing systems

A manufacturing system can be defined as a combination of humans, machinery, and equipment that are bound by a common material and information flow. The materials input to a manufacturing system are raw materials and energy.

What are industry 4.0 solutions for manufacturing

These technologies include:Big Data and AI analytics.Vertical and horizontal integration.Cloud computing.Augmented reality.Industrial Internet of Things.Additive manufacturing (also known as 3D printing)Autonomous robots.Simulation or digital twins.

What are the 5 types of manufacturing

The five types of manufacturing processesRepetitive manufacturing.Discrete manufacturing.Job shop manufacturing.Process manufacturing (continuous)Process manufacturing (batch)

What are the 5 types of software used in manufacturing

These types of software include:Enterprise Resource Planning (ERP).Manufacturing Execution Systems (MES).Quality Management Systems (QMS).Material Requirements Planning (MRP).Supply Chain Management (SCM).Customer Relationship Management (CRM).Bill of Materials (BoM).Inventory management.

What are Level 3 systems in manufacturing

The Manufacturing Execution System – or MES – is the IT system used to manage the entire manufacturing operations across your factory. The MES integrates data from Level 1 and Level 2 systems to build a comprehensive real-time view of the factory that can be used to control and monitor operations.

What are the five manufacturing

The five types of manufacturing processes

Repetitive manufacturing. Discrete manufacturing. Job shop manufacturing. Process manufacturing (continuous) Process manufacturing (batch)

What are the levels of manufacturing system

2. Here, manufacturing activities are divided into a hierarchy of six different levels: enterprise, factory or facility, line, cell or machine, tooling and setup, and process (e.g., physical interactions that process material to create a product, such as material removal at the tool-chip interface in machining) [14].

Why is Industry 4.0 important in manufacturing

Industry 4.0 technology helps you manage and optimize all aspects of your manufacturing processes and supply chain. It gives you access to the real-time data and insights you need to make smarter, faster decisions about your business, which can ultimately boost the efficiency and profitability of your entire operation.

What is Industry 4.0 technologies examples

It encompasses a set of technologies that include industrial IoT networks, AI, Big Data, robotics, and automation. Industry 4.0 allows for smart manufacturing and the creation of intelligent factories.

What are the 7 steps of manufacturing

Steps of the Manufacturing ProcessDevelop the Product Vision. The product vision is the seed the finished goods will grow from.Research the Vision.Design the Product.Finalize the Design.Test the Prototype.Manufacture the Product.Get Feedback and Do More Testing.Official Release.

What is Level 5 manufacturing

The IoSCM Level 5 Diploma in Manufacturing and Production Management course is designed for professionals who have experience in the manufacturing and production industry and want to expand their knowledge further, up to a middle management level.

What are the 4 types of system software

Types of System Software. System software is essential for a computer to function properly. And the most common types of system software are operating systems, device drivers, middleware, utilities, and programming language interpreters.

What are the 4 main types of software

Among the various categories of software, the most common types include the following:Application software.System software.Driver software.Middleware.Programming software.

What is Level 4 manufacturing

Production Level 4 refers to the increase in manufacturing robustness through the use of agile responsiveness to external influences, based on artificial intelligence methods.

What are the three basic types of production system

There are three common types of basic production systems: the batch system, the continuous system, and the project system. In the batch system, general-purpose equipment and methods are used to produce small quantities of output (goods or services) with specifications that vary greatly from one batch to the next.

What are the 5 Ms of manufacturing

Lean is an all-encompassing philosophy that takes the 5 M's (Man, Material, Machines, Methods, and Money) and harmonizes or helps orchestrate them together for the best possible outcome in your manufacturing operations. If you do not know the 5 M's, here's a brief overview of how the 5 M's relate to lean automation.

What are the 6 main applications of Industry 4.0 today

analytics and intelligence: advanced analytics, machine learning, artificial intelligence. human–machine interaction: virtual reality (VR) and augmented reality (AR), robotics and automation, autonomous guided vehicles. advanced engineering: additive manufacturing (such as, 3-D printing), renewable energy, …

What is the Industry 4.0 structure

Industry 4.0 can be defined as the integration of intelligent digital technologies into manufacturing and industrial processes. It encompasses a set of technologies that include industrial IoT networks, AI, Big Data, robotics, and automation.

What is Industry 4.0 system

Industry 4.0 is revolutionizing the way companies manufacture, improve and distribute their products. Manufacturers are integrating new technologies, including Internet of Things (IoT), cloud computing and analytics, and AI and machine learning into their production facilities and throughout their operations.

What are the 5 stages of manufacturing

Each stage has purpose and goals, and it is important that in each phase the goals are met before proceeding to the next. The 5 stages are development, pre-production, production, post-production, and distribution.

What is 5p in manufacturing

The division of production management functions in to 5 p's (product, plant, programme, processes and people) will provide useful conceptual framework for the various activities performed by production or operations manager.

What is level 1 in manufacturing

The Manufacturing Technician Level 1 (MT1) certification program was developed to meet the growing employment demands of the manufacturing industry. The MT1 program addresses the core industry-wide skills standards required for skilled production occupations in all sectors of manufacturing.

What are the 5 types of system software

Types of System SoftwareOperating System. Operating systems are the most important type of system software.Device Drivers.Firmware.BIOS and UEFI.Programming Language Translator.Utilities.