What is one key element of lean

"The core idea behind lean is maximizing customer value while minimizing waste," states LEI. "Simply put, lean means creating more value for customers with fewer resources." A lean organization understands customer value and focuses its key processes on continuous improvements.

What are the steps of the lean process

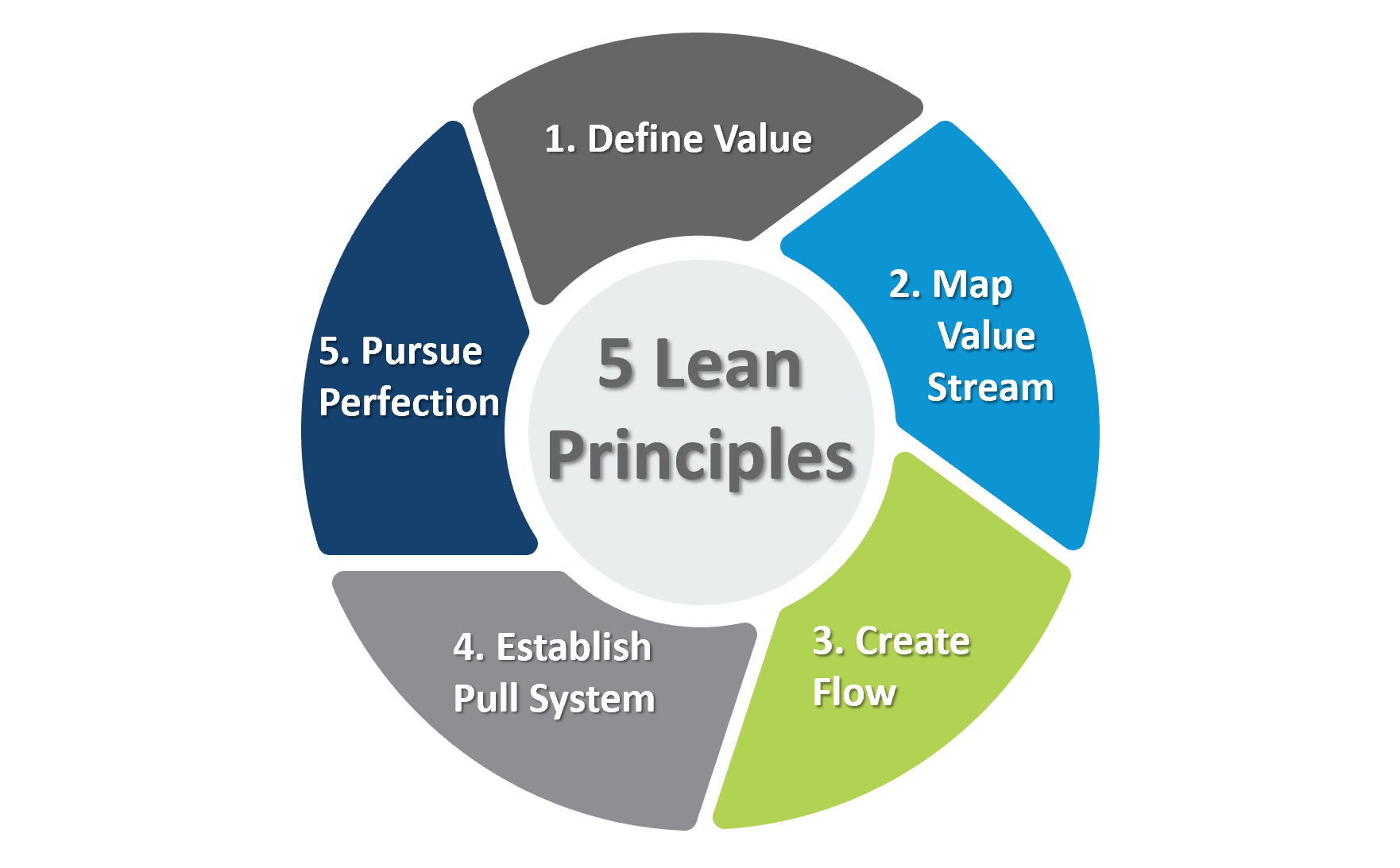

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. The next sections provides a detailed overview of each principle.

What are the principles of lean thinking

Q2: What are the five principles of Lean thinking The five lean principles include value, value stream, flow, pull, and perfection. These five principles rely on the two pillars of lean: continuous improvement and respect for people.

What are the principles of lean production

Lean manufacturing has enabled businesses to increase production, reduce costs, improve quality, and increase profits by following five key principles: identify value, map the value stream, create flow, establish pull and seek perfection.

What are the main elements of work lean

These elements help you understand what you are trying to achieve in terms of making a successful and sustainable change in a business.Specify value from the customer's perspective.Value stream.Flow.Pull.Perfection.

What are the key elements in lean methodology

The 5 Key Concepts of Lean Process ImprovementIdentify Value. In a lean process solution, everything starts with value.Stream of Value. Creating a visual value stream map is key to visualizing the workflow of your business.Flow.Pull.Continuous Improvement.

What is 5S lean concept

Method and Implementation Approach. 5S is a cyclical methodology: sort, set in order, shine, standardize, sustain the cycle. This results in continuous improvement.

What is 5S lean

THE BIG IDEA. 5S is a five-step methodology for creating a more organized and productive workspace: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.

What are the 5 steps of Lean thinking model

The five principles are considered a recipe for improving workplace efficiency and include: 1) Defining Value, 2) Mapping the Value Stream, 3) Creating Flow, 4) Using a Pull System, and 5) Pursuing Perfection.

What is Lean leadership principles

Lean leadership is a management philosophy and approach that focuses on continuous improvement, waste reduction, and increased organizational efficiency.

What are the 4 components of lean production

Just in time production (JIT) Cell production. Kaizen (Continuous improvement) Quality improvement and management.

What are the 10 basic elements of lean production

To help you gain a comprehensive understanding of lean manufacturing, here are 10 things you should know:Leveled Production.Continuous Improvement.Efficiency Through a Customer-First Approach.Total Productive Maintenance (TPM)Streamlining Processes.Develop Error-Proof Processes.Focus on Quality.One-Piece Flow.

What are the 5 dimensions of lean

Lean implementation is comprised of five main dimensions, which are transactional, organizational, spatial, time, and resources. Collectively, these dimensions help companies function more effectively and efficiently throughout the production process.

What are the 4 elements of lean management system

To me, it's easier to think of the definition in four elements.Element 1: To Serve and Develop People.Element 2: Through Human Interactions and Relationships.Element 3: Toward the Achievement of Goals that Support Purpose.Element 4: Creating More Value for All Stakeholders.

What are the 5 key principles of the lean startup methodology

Steve Blank and Eric Ries coined the term “lean startup” in the early 2000s. It is based on five principles: Entrepreneurs are everywhere, Entrepreneurship is management, Validated Learning, Innovation Accounting, BUILD-MEASURE-LEARN.

What are the 5 principles of 5S

When translated to English (with the Japanese original in brackets), the principles of 5S are as follows:Sort (Seiri)Set in order (Seiton)Shine (Seiso)Standardize (Seiketsu)Sustain (Shitsuke)

What are the 5S principles and examples

The Steps of 5SSort. Seiri (tidiness) Remove unnecessary items from each area.Set In Order. Seiton (orderliness) Organize and identify storage for efficient use.Shine. Seiso (cleanliness) Clean and inspect each area regularly.Standardize. Seiketsu (standardization)Sustain. Shitsuke (discipline)

Is 5S a lean tool

The 5S System is a lean manufacturing tool that helps to clean and organize the workplace, as well as improve how things are done through standardization.

What is 5S or 6S lean

6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety.

What are the 5 dimensions of Lean

Lean implementation is comprised of five main dimensions, which are transactional, organizational, spatial, time, and resources. Collectively, these dimensions help companies function more effectively and efficiently throughout the production process.

What is 5S concept

The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

What are the 4 things a lean leader must do

There are four duties that Lean leaders must fulfill:Commit. The practice of Lean isn't a sometimes thing.Engage. Executive investment in Lean initiatives is one way that employees will judge how important it is to the company.Coach.Organize.

What are the roles in lean

Four key roles in any Lean program are Sponsor, Facilitator, Leader and Team.

What are the 5S of lean manufacturing

The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment.

What are the 7 areas of lean

The Lean theory describes 7 major areas where you can identify Muda activities, more popular as the seven wastes of Lean.Transportation. This type of waste is when you move resources (materials), and the movement doesn't add value to the product.Inventory.Motion.Waiting.Overproduction.Over-processing.Defects.