What are the 5 principles of the lean model

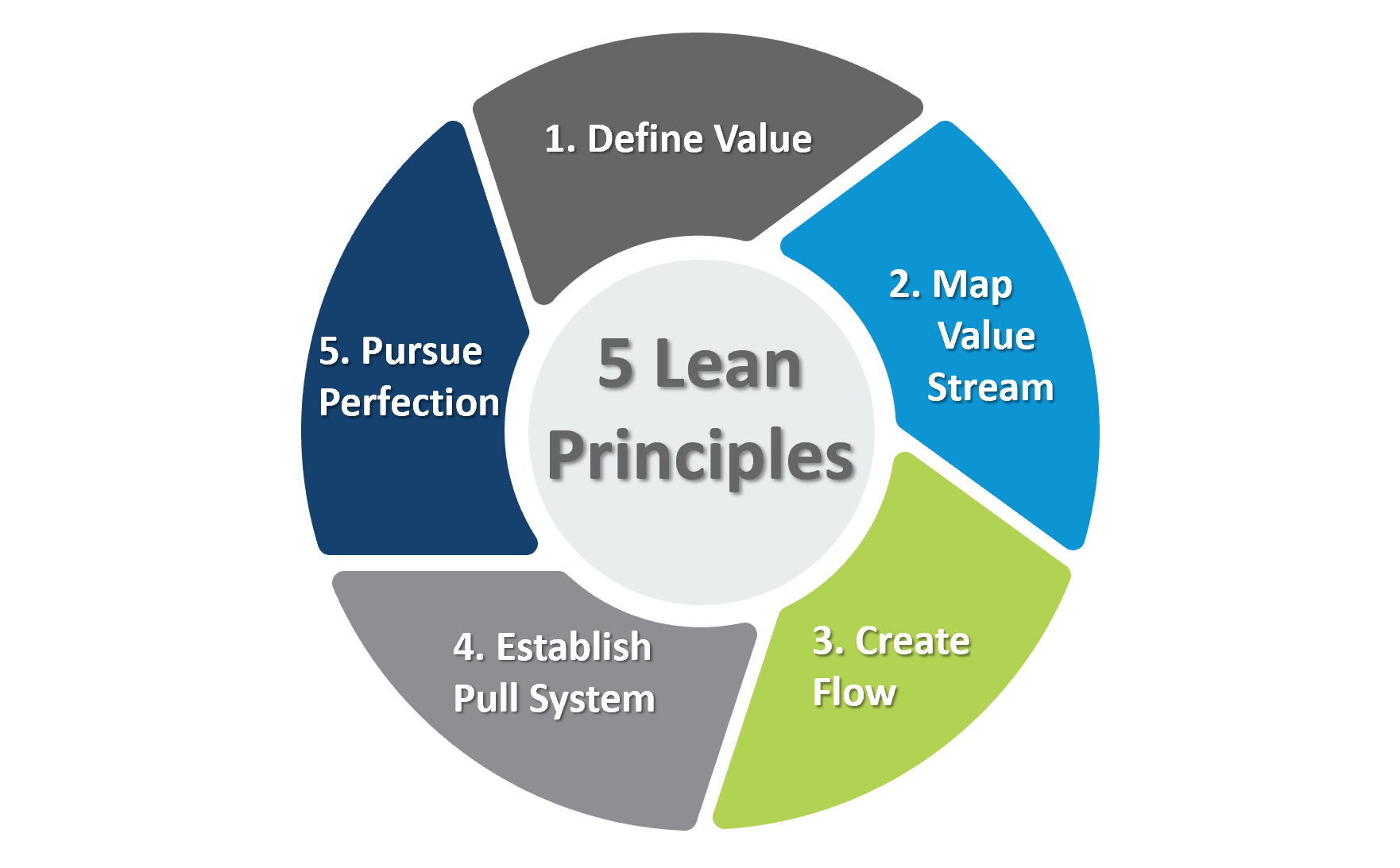

The five principles are considered a recipe for improving workplace efficiency and include: 1) Defining Value, 2) Mapping the Value Stream, 3) Creating Flow, 4) Using a Pull System, and 5) Pursuing Perfection.

What are the 5 elements of lean production

According to Womack and Jones, there are five key lean principles: value, value stream, flow, pull, and perfection.

What are the principles of lean production

Lean manufacturing has enabled businesses to increase production, reduce costs, improve quality, and increase profits by following five key principles: identify value, map the value stream, create flow, establish pull and seek perfection.

What are the 5 key principles of lean system in IOT

The five principles of lean manufacturing include defining value, mapping the value stream, creating flow, using a pull system, and pursuing perfection. These five principles are outlined in more detail below: Define Value – Lean manufacturing principles aim to add value to the end customer.

What are the 5 dimensions of lean

Lean implementation is comprised of five main dimensions, which are transactional, organizational, spatial, time, and resources. Collectively, these dimensions help companies function more effectively and efficiently throughout the production process.

What is 5S concept

5S is a five-step methodology for creating a more organized and productive workspace: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.

What are the 4 components of lean production

Just in time production (JIT) Cell production. Kaizen (Continuous improvement) Quality improvement and management.

What are the 4 principles of Lean

Our approach is based on the basic Principles of Lean:

Define value from the standpoint of the customer. Identify value and remove waste. Replace waste with value. Continuously improve.

What are the 7 ways in lean

The Lean theory describes 7 major areas where you can identify Muda activities, more popular as the seven wastes of Lean.Transportation. This type of waste is when you move resources (materials), and the movement doesn't add value to the product.Inventory.Motion.Waiting.Overproduction.Over-processing.Defects.

Which are the 5 dimensions

The first three are hight, width, and depth. You can see these on the cube itself, you don't even need to kick it to get a feel for them. The last one is time, and you see this one over the progression of its movement. This dimension is time.

What is 5S quality

5S is a method for workplace organization and improvement that originated in Japan. It stands for five (5) Japanese words that start with the letter 'S': Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. The English translation of these terms is sort, set in order, shine, standardize, and sustain.

What are the five example of 5S

The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

What are the 4 goals of lean

To recap, the goals of lean manufacturing are to improve the quality of products, eliminate unnecessary waste, reduce production times and reduce total costs.

What are the 7 areas of lean

The Lean theory describes 7 major areas where you can identify Muda activities, more popular as the seven wastes of Lean.Transportation. This type of waste is when you move resources (materials), and the movement doesn't add value to the product.Inventory.Motion.Waiting.Overproduction.Over-processing.Defects.

What are the 10 basic elements of lean production

To help you gain a comprehensive understanding of lean manufacturing, here are 10 things you should know:Leveled Production.Continuous Improvement.Efficiency Through a Customer-First Approach.Total Productive Maintenance (TPM)Streamlining Processes.Develop Error-Proof Processes.Focus on Quality.One-Piece Flow.

What are the 10 rules of lean production

Principles of lean production include: eliminating waste; minimizing inventory; maximizing flow; pulling production from customer demand; meeting customer requirements; doing it right first time; empowering workers; designing for rapid changeover; partnering with suppliers; creating a culture of continuous improvement …

What is 5 dimensional concept

In physics, the 5th dimension is a microdimension of space too small to see that has mathematical value in theoretical models of the universe, like string theory.

What is the meaning of 5 dimensions

A five-dimensional space is a space with five dimensions. In mathematics, a sequence of N numbers can represent a location in an N-dimensional space. If interpreted physically, that is one more than the usual three spatial dimensions and the fourth dimension of time used in relativistic physics.

What are the 5S in Six Sigma

The goal of 5S is to create a clean, uncluttered environment that allows people to do their jobs without wasting time, while also lowering the risk of injury. The five words in 5S represent the five steps to accomplish this goal. They are sort, set, shine, standardize and sustain.

What is the 5S model of Six Sigma

In simple terms, the five S methodology helps a workplace remove items that are no longer needed (sort), organize the items to optimize efficiency and flow (straighten), clean the area in order to more easily identify problems (shine), implement color coding and labels to stay consistent with other areas (standardize) …

What are the 5S principles and examples

The Steps of 5SSort. Seiri (tidiness) Remove unnecessary items from each area.Set In Order. Seiton (orderliness) Organize and identify storage for efficient use.Shine. Seiso (cleanliness) Clean and inspect each area regularly.Standardize. Seiketsu (standardization)Sustain. Shitsuke (discipline)

What are the 5 words in 5S and its meaning

5S is the principles of work environment improvement derived from the Japanese words seiri, seiton, seiso, seiketsu, and shitsuke. In English the five Ss are respectively described Sort, Set Shine, Standardize, and Sustain.

What are the 3 types of lean

The labels muda, mura and muri are also used in lean development, an Agile software methodology inspired by the Toyota Way.

What are the 7 steps lean manufacturing

What is lean manufacturing The top 7 principles for manufacturers to improve processes1) Elimination of waste.2) Valuing the human element.3) Seeking perfection.4) Mapping the value stream.5) Reducing and preventing mistakes.6) Identifying loss of value.7) Automatically finding defects.

What are the 7 areas of Lean

The Lean theory describes 7 major areas where you can identify Muda activities, more popular as the seven wastes of Lean.Transportation. This type of waste is when you move resources (materials), and the movement doesn't add value to the product.Inventory.Motion.Waiting.Overproduction.Over-processing.Defects.