What are the 5 principles of the lean model

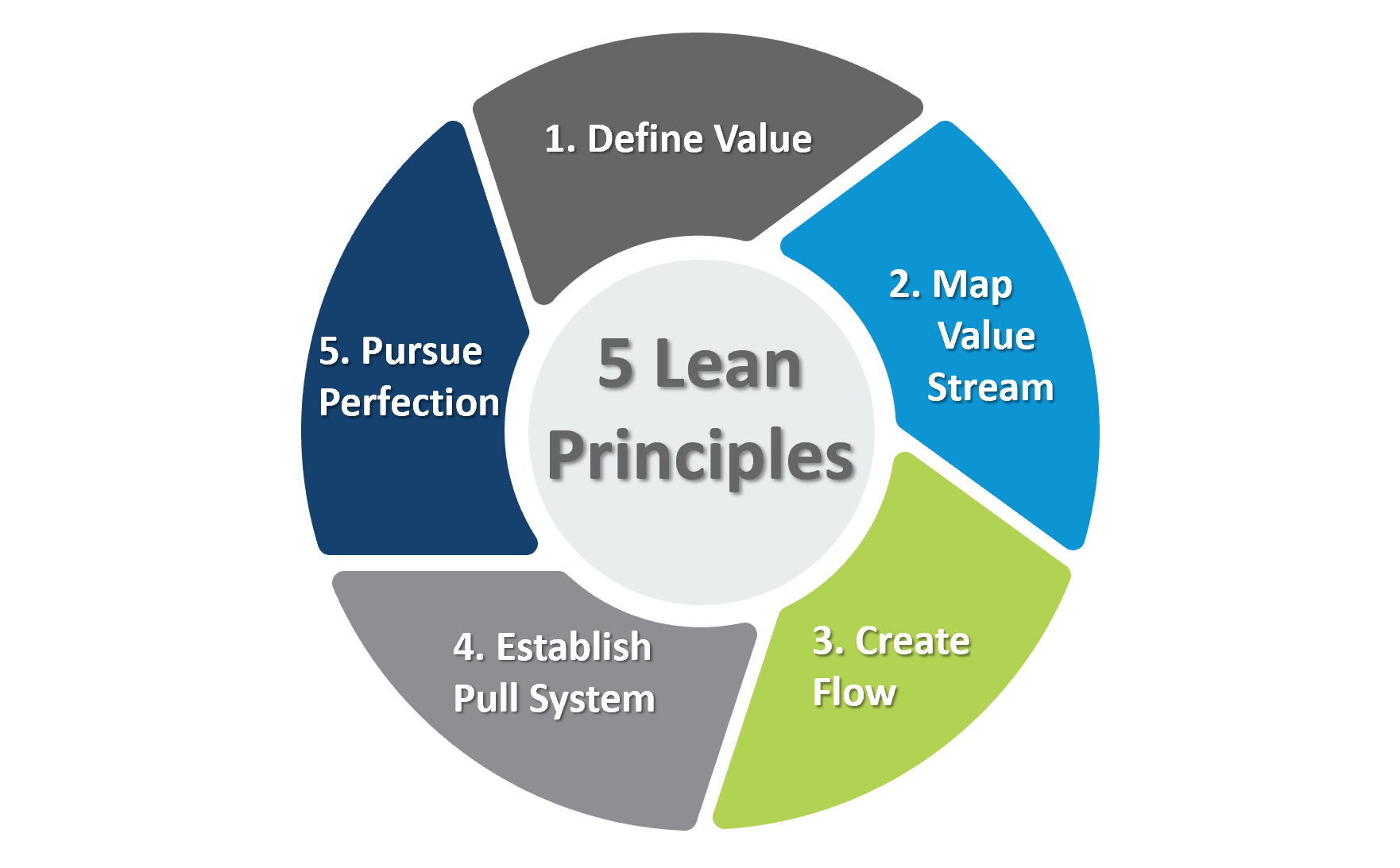

The five principles are considered a recipe for improving workplace efficiency and include: 1) Defining Value, 2) Mapping the Value Stream, 3) Creating Flow, 4) Using a Pull System, and 5) Pursuing Perfection.

What are the 5 lean principles explain each one in terms of a manufacturing facility

The five core principles of lean manufacturing are defined as value, the value stream, flow, pull and perfection. These are now used as the basis to implement lean.

What are the principles of 5S aim at achieving

5S is a cyclical methodology: sort, set in order, shine, standardize, sustain the cycle. This results in continuous improvement.

What are the 4 stages of lean methodology

The 4 Steps of the Lean Startup CycleStep #1 – Business Model Canvas.Step #2 – Formulating a Hypothesis.Step #3 – Minimum Viable Product (MVP)Step #4 Learning.

What are the 5 dimensions of lean

Lean implementation is comprised of five main dimensions, which are transactional, organizational, spatial, time, and resources. Collectively, these dimensions help companies function more effectively and efficiently throughout the production process.

What are the principles of lean production

Lean manufacturing has enabled businesses to increase production, reduce costs, improve quality, and increase profits by following five key principles: identify value, map the value stream, create flow, establish pull and seek perfection.

What are the 5 P’s of lean manufacturing

The constituents of the 5P model are: 1) Plan, 2) Process, 3) People, 4) Possessions, and 5) Profits.

What are the 5 Ms of lean manufacturing

Lean is an all-encompassing philosophy that takes the 5 M's (Man, Material, Machines, Methods, and Money) and harmonizes or helps orchestrate them together for the best possible outcome in your manufacturing operations. If you do not know the 5 M's, here's a brief overview of how the 5 M's relate to lean automation.

What are the 5 principles of 5S

When translated to English (with the Japanese original in brackets), the principles of 5S are as follows:Sort (Seiri)Set in order (Seiton)Shine (Seiso)Standardize (Seiketsu)Sustain (Shitsuke)

What are the 5S principles and examples

The Steps of 5SSort. Seiri (tidiness) Remove unnecessary items from each area.Set In Order. Seiton (orderliness) Organize and identify storage for efficient use.Shine. Seiso (cleanliness) Clean and inspect each area regularly.Standardize. Seiketsu (standardization)Sustain. Shitsuke (discipline)

What are the 4 components of lean production

Just in time production (JIT) Cell production. Kaizen (Continuous improvement) Quality improvement and management.

Who developed the 5 principles of lean

Lean was originally created by Toyota to eliminate waste and inefficiency in its manufacturing operations. The process became so successful that it has been embraced in manufacturing sectors around the world.

Which are the 5 dimensions

The first three are hight, width, and depth. You can see these on the cube itself, you don't even need to kick it to get a feel for them. The last one is time, and you see this one over the progression of its movement. This dimension is time.

What is 5S concept

The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

What are the 5 P’s of performance

Purpose, People, Processes, Passion, and Performance

This is often the stated vision and mission that are supported by the organization's values. These leaders help everyone in the organization see how the work they do contributes to that higher PURPOSE.

What are the 5 M’s of quality management

If we get back to basics, we know that product quality is rooted in the control of the “Five Ms” – material, man, machine, measure, and method.

What is Level 5 manufacturing

The IoSCM Level 5 Diploma in Manufacturing and Production Management course is designed for professionals who have experience in the manufacturing and production industry and want to expand their knowledge further, up to a middle management level.

What is 5S system in production

THE BIG IDEA. 5S is a five-step methodology for creating a more organized and productive workspace: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.

What are the 5S of lean Six Sigma

The five words in 5S represent the five steps to accomplish this goal. They are sort, set, shine, standardize and sustain. Lean bases the words on the original Japanese: seiri, seiton, seiso, seiketsu and shitsuke.

What is 5 dimensional concept

In physics, the 5th dimension is a microdimension of space too small to see that has mathematical value in theoretical models of the universe, like string theory.

What is the meaning of 5 dimensions

A five-dimensional space is a space with five dimensions. In mathematics, a sequence of N numbers can represent a location in an N-dimensional space. If interpreted physically, that is one more than the usual three spatial dimensions and the fourth dimension of time used in relativistic physics.

What is 5S Kaizen

5S, together with Kaizen, seeks to “humanize” work by eliminating wasted effort, making the work itself easier and employees more productive and happier. The 5S model emphasizes structure, order, cleanliness, standardization and a disciplined approach to sustaining the process.

What is the 5 P concept

The 5 P's of marketing – Product, Price, Promotion, Place, and People – are a framework that helps guide marketing strategies and keep marketers focused on the right things. Let's take a deep dive into their importance for your brand.

What are the 5 P’s structure

Mintzberg developed his 5 Ps of Strategy as five different definitions of (or approaches to) developing strategy. He first wrote about the 5 Ps of Strategy in 1987. Each of the 5 Ps is a different approach to strategy. They are Plan, Ploy, Pattern, Position, and Perspective.

What are the 5Ms of production

Lean is an all-encompassing philosophy that takes the 5 M's (Man, Material, Machines, Methods, and Money) and harmonizes or helps orchestrate them together for the best possible outcome in your manufacturing operations. If you do not know the 5 M's, here's a brief overview of how the 5 M's relate to lean automation.