What are the 7 steps lean manufacturing

What is lean manufacturing The top 7 principles for manufacturers to improve processes1) Elimination of waste.2) Valuing the human element.3) Seeking perfection.4) Mapping the value stream.5) Reducing and preventing mistakes.6) Identifying loss of value.7) Automatically finding defects.

What are the 5 principles of lean manufacturing

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

What are the elements of a lean manufacturing system

The five core principles of lean manufacturing are defined as value, the value stream, flow, pull and perfection.

What are the 4 P’s in lean manufacturing

In addition to changing from silo to matrix management, implementing Lean follows four basic tenets, known as the four Ps of Lean thinking: purpose, process, people, and performance.

What are the 10 basic elements of lean production

To help you gain a comprehensive understanding of lean manufacturing, here are 10 things you should know:Leveled Production.Continuous Improvement.Efficiency Through a Customer-First Approach.Total Productive Maintenance (TPM)Streamlining Processes.Develop Error-Proof Processes.Focus on Quality.One-Piece Flow.

What are the 7 steps to a successful Lean Six Sigma implementation

How to Implement Lean Six SigmaGet Strategic Management Support.Raise Awareness.Establish Ownership.Define What Value Is.Set Priorities.Gather Measurement Data.Establish Control to Sustain Improvement.

What are the 10 rules of lean production

Principles of lean production include: eliminating waste; minimizing inventory; maximizing flow; pulling production from customer demand; meeting customer requirements; doing it right first time; empowering workers; designing for rapid changeover; partnering with suppliers; creating a culture of continuous improvement …

What are the 5 S’s of lean manufacturing Six Sigma

5S is a cyclical methodology: sort, set in order, shine, standardize, sustain the cycle.

What are the 3 components of lean manufacturing

The Lean approach to business processes, originally derived from the enormously influential Toyota production system (TPS) , is based on three fundamental principles: delivering value as defined by the customer, eliminating waste, and continuous improvement.

What are the 5 production elements

Here are the 5 elements of production:The object of production: the product.Agents of production: the people in charge of making products, as well as the machines, tools, jigs, and other equipment that assist them.Methods: the means by which actions are performed.

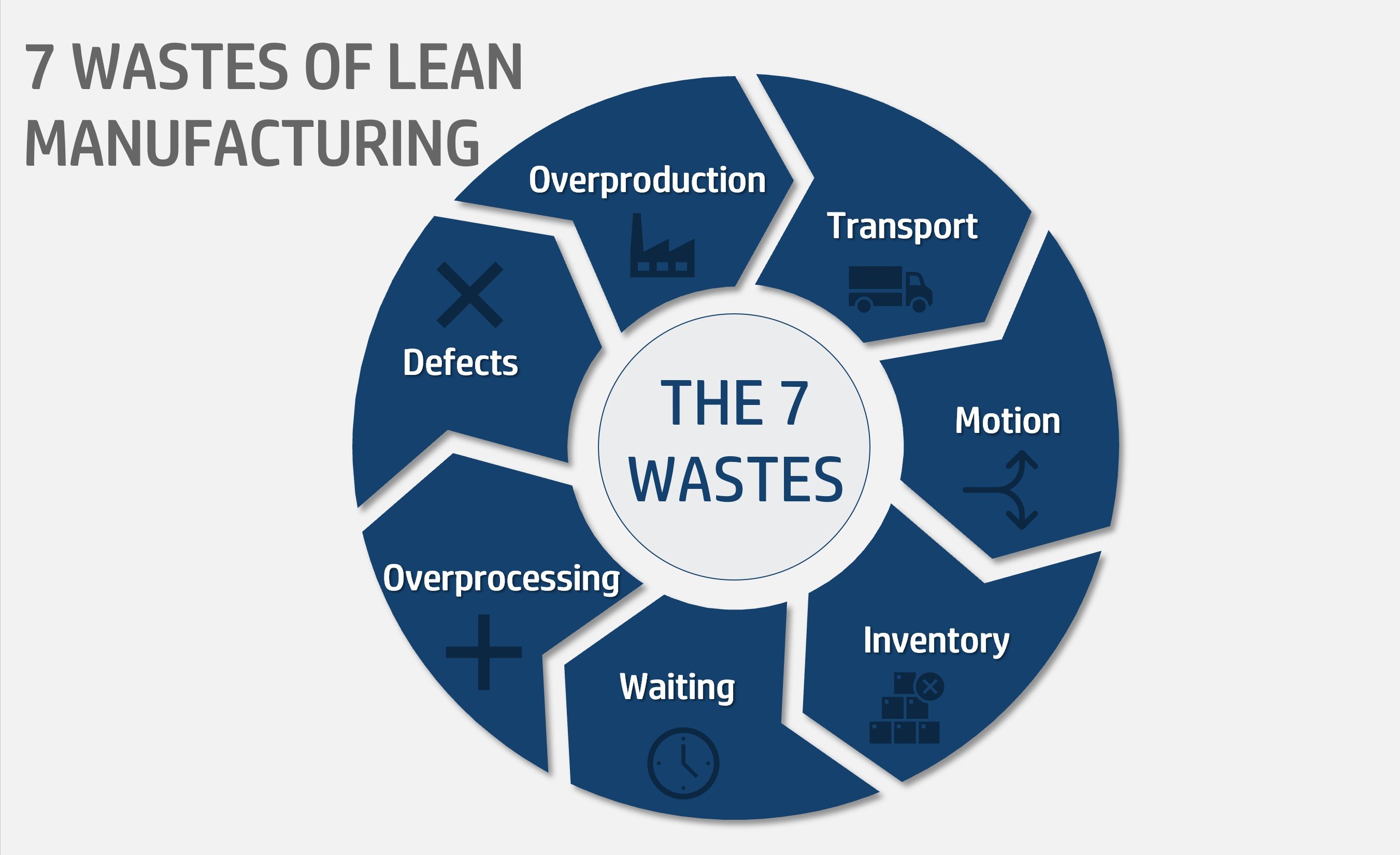

What are the 8 ways of Lean Six Sigma

Lean Six Sigma categorizes waste into eight key areas, packaged appropriately with the acronym DOWNTIME.D. Defects.O. Overproduction.W. Waiting.N. Non-Utilized talent.T. Transportation.I. Inventory.M. Motion.E. Extra Processing.

What are the seven principles of Lean Six Sigma

There are two Six Sigma methodologies: DMAIC and DMADV. DMAIC (Define, Measure, Analyze, Improve, Control) is an improvement methodology used when a process needs to meet desired performance levels. DMADV (Define, Measure, Analyze, Design, Verify) is a design methodology used when creating or improving a process.

What are the 4 rules of lean

Kent Bowen boiled down the essence of all lean systems to these Lean 4 Rules In Use:Rule 1) Clearly specify all Activities.Rule 2) Clearly define all Connections. to every customer and supplier.Rule 3) Clearly define all Pathways.Rule 4) Continuously Improve.

What are the 3 methods of lean production

The main methods of lean production are summarised below:Cell production. In traditional production, products were manufactured in separate areas (each with a responsibility for a different part of the manufacturing process) and many workers would work on their own, as on a production line.Kaizen.Just in time.

What is Lean vs 5S vs 6 sigma

While Lean helps in making processes more efficient, Six Sigma helps in finding the root cause of problems, and 5S helps in removing items that are no longer needed – helping keep the business streamlined and organised.

What is Six Sigma 5 steps

The Six Sigma Methodology comprises five data-driven stages — Define, Measure, Analyze, Improve and Control (DMAIC). When fully implemented, DMAIC standardizes an organization's problem-solving approach and shapes how it ideates new process solutions.

Which are the 3 main tools in lean management

What Are Lean Tools

| Lean Tools | Summary |

|---|---|

| Just-in-Time (JIT) | On-demand system of production |

| Value Stream Mapping | Analyzing and optimizing a process |

| Overall Equipment Effectiveness (OEE) | Measure of productive time |

| Plan-Do-Check-Act (PDCA) | Method to manage change |

What are the 3 principles of lean

Lean Basics

The Lean approach to business processes, originally derived from the enormously influential Toyota production system (TPS) , is based on three fundamental principles: delivering value as defined by the customer, eliminating waste, and continuous improvement.

What are the 6 parts of production planning

The following are main elements of Production Planning and Control:Routing.Loading.Scheduling.Dispatching.Follow up.Inspection.Corrective.

What are the 5 types of production

The five main types of the production process are Mass production, Batch production, job production, Just-In-Time production, and flexible manufacturing system.

What are the 7 S of Six Sigma

7S is the new terminology consists of the seven phases namely Sort, Set in order, Shine, Standardize, Sustain or Self Discipline, Safety and Spirit. The paper explains the methodology, action steps, resources required and target outcomes for the implementation of 7S as a tool of organizing workplace scenario.

What are the 5 principles of Six Sigma

5 Lean Six Sigma PrinciplesWork for the customer. The primary goal of any change you want to implement should be to deliver maximum benefit to the customer.Find your problem and focus on it.Remove variation and bottlenecks.Communicate clearly and train team members.Be flexible and responsive.

What are the 5 elements of 6 Sigma

5 Lean Six Sigma PrinciplesWork for the customer. The primary goal of any change you want to implement should be to deliver maximum benefit to the customer.Find your problem and focus on it.Remove variation and bottlenecks.Communicate clearly and train team members.Be flexible and responsive.

What are the 7 principles for

The 7 Principles of the Constitution (popular sovereignty, limited government, separation of powers, checks and balances, judicial review, federalism, and republicanism) explained.

What are the 5 stages of lean

What Are the 5 Lean Management PrinciplesIdentifying Value. To lay the foundations of a Lean process, you need first to identify the team's work value.Mapping the Value Stream. The second of the 5 principles of Lean is all about the stream of value.Creating a Flow.Establishing Pull.Seeking Constant Improvement.