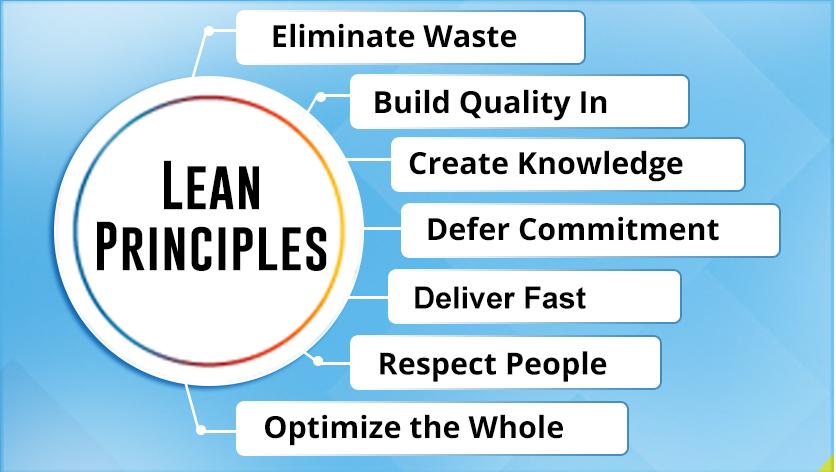

What are the 7 lean principles

The seven Lean principles are:Eliminate waste.Build quality in.Create knowledge.Defer commitment.Deliver fast.Respect people.Optimize the whole.

What are the 7 steps lean manufacturing

What is lean manufacturing The top 7 principles for manufacturers to improve processes1) Elimination of waste.2) Valuing the human element.3) Seeking perfection.4) Mapping the value stream.5) Reducing and preventing mistakes.6) Identifying loss of value.7) Automatically finding defects.

Which of the following are 5 lean principles

The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

Why lean is important

Lean can help teams identify inefficiencies and implement improved workflows that save time and money through a time-tested process of standardization, visualization, and organization.

What are 7 wastes

The 7 Wastes of Lean ProductionOverproduction. Overproduction is the most obvious form of manufacturing waste.Inventory. This is the waste that is associated with unprocessed inventory.Defects.Motion.Over-processing.Waiting.Transportation.Additional forms of waste.

Is Six Sigma a Lean principle

Lean Six Sigma is based on a set of principles that are a combination of Lean methodology and the Six Sigma approach. While Lean focuses mainly on eliminating wasteful activities, Six Sigma aims to improve quality by removing causes of defects.

What are the 10 basic elements of lean production

To help you gain a comprehensive understanding of lean manufacturing, here are 10 things you should know:Leveled Production.Continuous Improvement.Efficiency Through a Customer-First Approach.Total Productive Maintenance (TPM)Streamlining Processes.Develop Error-Proof Processes.Focus on Quality.One-Piece Flow.

What are the 5 stages of lean

The Five Steps of Lean ImplementationStep 1: Specify Value. Define value from the perspective of the final customer.Step 2: Map.Step 3: Flow.Step 4: Pull.Step 5: Perfection.

What are the five S’s 5S of lean

The 5S pillars, Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment.

What are the 5S of lean Six Sigma

The five words in 5S represent the five steps to accomplish this goal. They are sort, set, shine, standardize and sustain. Lean bases the words on the original Japanese: seiri, seiton, seiso, seiketsu and shitsuke.

Why should a company use lean

Increased Efficiency

In essence, it helps them eliminate production waste, reduce energy used to create products and services, and lowers production costs. By using lean manufacturing, this standardizes work for frontline employees in the production line.

Why is lean important in the workplace

Lean management decreases the number of wasteful activities, therefore allowing the workforce to increase their focus on tasks that produce value. Enhanced productivity and efficiency. Improved focus leads to a more productive and efficient workforce since attention is not given to unnecessary activities.

Are there 7 or 8 wastes of lean

Originally there were seven wastes identified by Taiichi Ohno for the Toyota Production System. As lean evolved into the rest of the enterprise and around the world, an eighth waste, non-utilized talent, was identified. Jean Cunningham and others use an acronym, “DOWNTIME”, to help remember the wastes.

What is 7 wastes of lean

The 7 Wastes of Lean ProductionOverproduction. Overproduction is the most obvious form of manufacturing waste.Inventory. This is the waste that is associated with unprocessed inventory.Defects.Motion.Over-processing.Waiting.Transportation.Additional forms of waste.

Which is better Lean Six Sigma or Six Sigma

In simple, the focus of Six Sigma is on the customer and the end product, while Lean Six Sigma focuses on waste and production methods. If you are an experienced professional and have supported quality improvement projects, Six Sigma Green Belt is good for you.

What is lean vs Six Sigma vs

Lean focuses on analyzing workflow to reduce cycle time and eliminate waste. Lean strives to maximize value to the customer while using a few resources as possible. Six Sigma strives for near perfect results that will reduce costs and achieve higher levels of customer satisfaction.

What are the 4 methods of lean production

These are:The key aspects of lean production that you should be aware of are:Time based management.Simultaneous engineering.Just in time production (JIT)Cell production.Kaizen (Continuous improvement)Quality improvement and management.

What is lean checklist

Click on the Picture to Learn About More Lean Tools. A checklist is a tool that can be used to ensure that you have everything required to set up and run your next operation. It may also be used to ensure that important steps or actions have been taken that are important for an operation.

What are the 4 stages of lean methodology

The 4 Steps of the Lean Startup CycleStep #1 – Business Model Canvas.Step #2 – Formulating a Hypothesis.Step #3 – Minimum Viable Product (MVP)Step #4 Learning.

What are the 3 types of lean

The labels muda, mura and muri are also used in lean development, an Agile software methodology inspired by the Toyota Way.

Is 5S lean or Six Sigma

The 5S system is a key component of Lean Six Sigma. Developed at Toyota, the 5S approach creates safer, more efficient workstations that allow employees to improve and sustain higher productivity. The term 5S refers to the five steps of the system.

Is lean and 5S the same thing

Don't confuse the approach to 5S as a substitute for the whole lean philosophy. 5S is just one of the many steps involved with adopting a lean mindset and then turning it into a continuous improvement mentality for all members of the organization. Just-in-time production is a best practice of lean assembly.

What is Lean vs 5S vs 6 sigma

While Lean helps in making processes more efficient, Six Sigma helps in finding the root cause of problems, and 5S helps in removing items that are no longer needed – helping keep the business streamlined and organised.

What is 5S vs Kaizen vs Six Sigma

With Kaizen's focus on culture, 5S's on environment, Lean on waste and Six Sigma on defects and quality, we have a powerful combination of tools poised to transform organizations. What if Kaizen, Lean, 5S and Six Sigma are applied from time of booking a surgical case to hospital discharge and/or rehab

What is the most important thing in lean

At its core, all successful Lean systems are rooted in one thing: Respect for people. Lean systems are designed to maximize customer value while minimizing waste, out of respect for the customer. Out of respect for employees, Lean systems encourage environments that allow everyone to do their best work.