What are the 7 waste

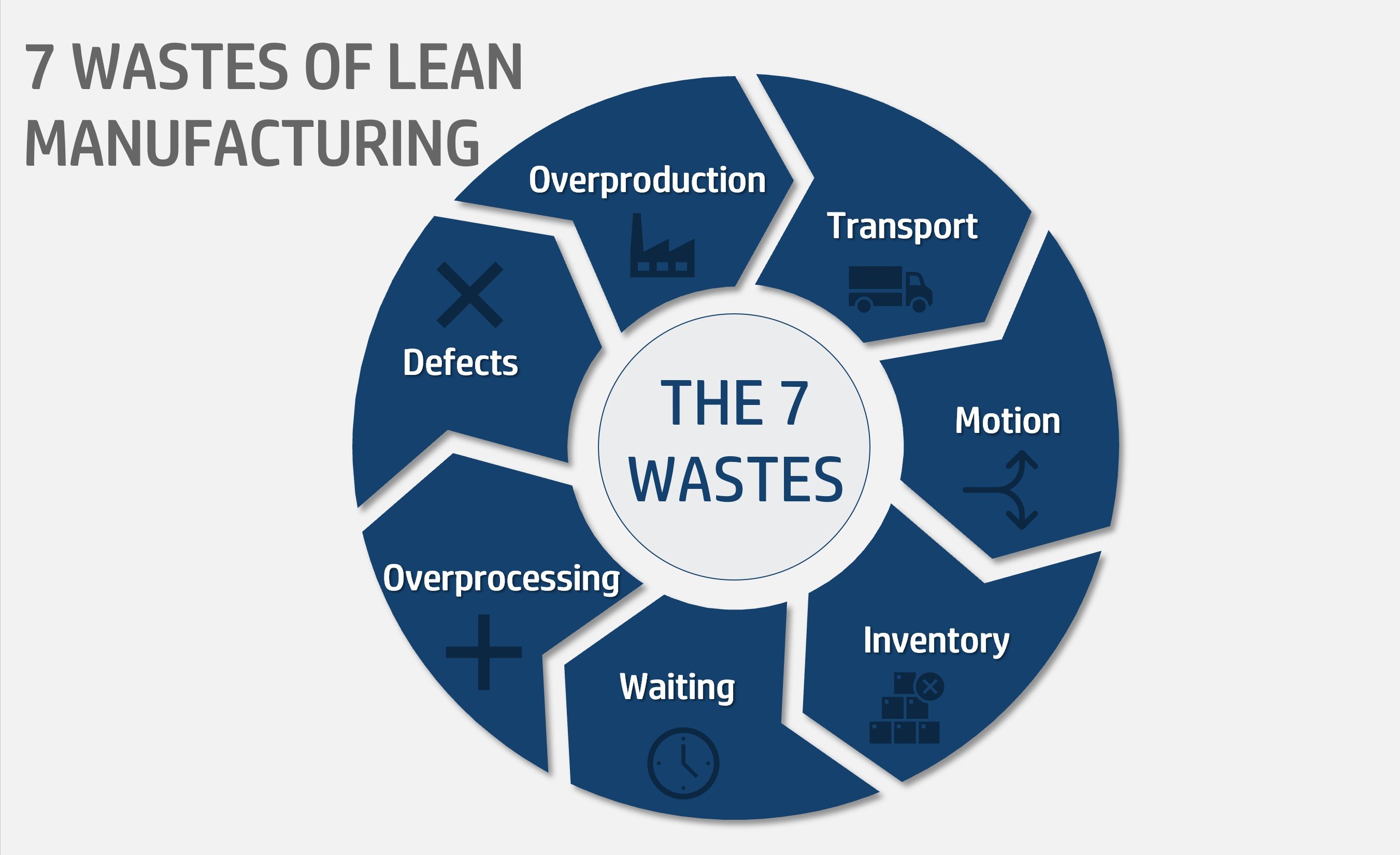

The 7 Wastes of Lean ProductionOverproduction. Overproduction is the most obvious form of manufacturing waste.Inventory. This is the waste that is associated with unprocessed inventory.Defects.Motion.Over-processing.Waiting.Transportation.Additional forms of waste.

What are the 8 forms of waste and provide an example of each

The 8 wastesOverproduction. Producing more or sooner than needed.Waiting. Idle workers or machines.Inefficient operations. Operations that aren't efficient or necessary and don't add value for the customer.Transport. Excess movement of materials, products or information.Inventory.Motion.Poor quality.Misused resources.

What is an example of inventory waste

Manufacturing inventory waste could include broken machines sitting around, more finished products than demanded, extra materials taking up work space, and finished products that cannot be sold.

What is Muda or waste

Muda means wastefulness. Work that does not add value is divided into two categories: work that is necessary but not recognized by the customer as adding value — and work that simply is not necessary. The second type of Muda should be identified and eliminated. There are seven wastes recognized in Muda.

What is 7 or 8 waste

What are the 7 wastes in Lean Lean implementation focuses on eliminating the 7 wastes (now expanded to 8 wastes) as identified in any process. These are the wastes of: over-production, waiting, transportation, processing itself, stocks [inventories], motion, and making defective products.

What are the 8 type of waste in industry

An often used acronym for the 8 wastes of lean manufacturing is DOWNTIME which stands for: Defects, Overproduction, Waiting, Not utilising talent, Transportation, Inventory excess, Motion waste, Excess processing.

What are the 10 kinds of solid waste

Types of Solid WastesHousehold Hazardous Waste (HHW)Construction and Demolition Debris.Industrial/Commercial Waste.Hazardous Waste Lamps.Regulated Medical Waste.Used Electronic Equipment.Used Oil.Waste Tires.

What are the 8 classification of solid waste and its sources

CLASSIFICATION OF SOLID WASTES(i) Domestic/Residential Waste: This category of waste comprises the solid wastes that originate from single and multi-family household units.(ii) Municipal Waste:(iii) Commercial Waste:(iv) Institutional Waste:(v) Garbage:(vi) Rubbish:(vii) Ashes:(viii) Bulky Wastes:

What are 5 examples of waste materials

The major components are food waste, paper, plastic, rags, metal and glass, although demolition and construction debris is often included in collected waste, as are small quantities of hazardous waste, such as electric light bulbs, batteries, automotive parts and discarded medicines and chemicals.

What are 3 examples of waste products

Examples include municipal solid waste (household trash/refuse), hazardous waste, wastewater (such as sewage, which contains bodily wastes (feces and urine) and surface runoff), radioactive waste, and others.

What is Muri Mura and Muda

The Toyota Production System, and later on the concept of Lean, was developed around eliminating the three types of deviations that shows inefficient allocation of resources. The three types are Muda (waste), Mura (unevenness), and Muri (overburden).

Is Muda the Japanese word for waste

The Japanese word for waste is Muda. Muda is considered a non-value-added task within the process. It describes the concept of being useless and unnecessary. The generation of waste not only reduces the efficiency of the process but also makes the workflow unproductive.

What is 8 waste concept

What are the 8 wastes of lean An often used acronym for the 8 wastes of lean manufacturing is DOWNTIME which stands for: Defects, Overproduction, Waiting, Not utilising talent, Transportation, Inventory excess, Motion waste, Excess processing.

What are the 7 wastes in Six Sigma

Edwards Deming was the genesis for what is now called Lean Six Sigma. The idea is to cut waste across all resources: time, effort, people, processes, inventory, and production. According to Lean Six Sigma, the 7 Wastes are Inventory, Motion, Over-Processing, Overproduction, Waiting, Transport, and Defects.

What are 10 examples of industrial waste

Cafeteria refuse, dirt and gravel, masonry and mortar, scrap metals, gasoline, solvents, pesticides, weed grass and trees, wood and scrap lumber are examples of industrial waste.

What are the 8 elements of waste

To help focus efforts in this area, Lean practitioners developed a list of eight wastes which establish the most likely areas where waste will occur: defects, overproduction, transportation, non-value adding processing, motion, waiting, unused talent and inventory.

What are the 5 main types of waste

Types of WasteLiquid Waste. Liquid waste includes dirty water, wash water, organic liquids, waste detergents and sometimes rainwater.Solid Rubbish. Solid rubbish includes a large variety of items that may be found in households or commercial locations.Organic Waste.Recyclable Rubbish.Hazardous Waste.

What are the 10 types of solid waste

Food wastes, paper, cardboard, plastics, textiles, leather, yard wastes, wood, glass, metals, ashes, special wastes (e.g., bulky items, consumer electronics, white goods, batteries, oil, tires), and household hazardous wastes.).

What is the most common waste

Food is the most common form of waste, accounting for almost 50 percent of global MSW. Millions of tons of food is wasted every year, especially fruit and vegetables. Much like other waste forms, the United States is a major producer of food waste, generating almost 100 million metric tons of food waste every year.

What are the 8 wastes or muda in Lean terms

To help focus efforts in this area, Lean practitioners developed a list of eight wastes which establish the most likely areas where waste will occur: defects, overproduction, transportation, non-value adding processing, motion, waiting, unused talent and inventory.

What muri means

overburden or unreasonable

Muri is a Japanese term meaning “overburden or unreasonable”. It is one of the three types of waste (Muda, Mura, Muri) and a key concept in the Toyota Production System. In other words, you create Muri whenever you put your team under stress by demanding unreasonable or unnecessary work that exceeds their capacity.

What is Japanese for no waste

Mottainai

Mottainai is a centuries-old Japanese philosophy that embraces the idea of respecting resources and their value while also reducing waste. Its origins derive from two words—mottai (importance or sanctity) and nai (lack of something). Together they form the expression ”what a waste” or ”don't be wasteful.”

What is muda in English Japanese

Muda (無駄) is a Japanese word meaning "wasteful" and is a key concept in the Toyota Production System (TPS), the precursor to LEAN Manufacturing. According to Toyota, Muda is a process that does not add value.

What are the 8 general wastes in manufacturing

An often used acronym for the 8 wastes of lean manufacturing is DOWNTIME which stands for: Defects, Overproduction, Waiting, Not utilising talent, Transportation, Inventory excess, Motion waste, Excess processing.

What are the 5 principles and 8 wastes of lean manufacturing

The 8 wastes of lean manufacturing include:Defects. Defects impact time, money, resources and customer satisfaction.Excess Processing. Excess processing is a sign of a poorly designed process.Overproduction.Waiting.Inventory.Transportation.Motion.Non-Utilized Talent.